Making the most of Effectiveness: The Value of Genuine Komatsu Undercarriage Parts

Wiki Article

Efficient Solutions: Undercarriage Components for Heavy Equipment

Quality undercarriage parts play a substantial role in making sure the smooth procedure and longevity of heavy equipment. In this discussion, we will discover the importance of investing in superior undercarriage components, common wear difficulties encountered by hefty machinery operators, the benefits of prompt substitutes, standards for selecting trustworthy suppliers, and important maintenance ideas to expand the lifespan of undercarriage components.Significance of High Quality Undercarriage Components

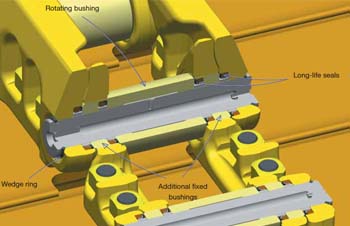

Quality undercarriage components are crucial components in guaranteeing the resilience and performance of heavy machinery. The undercarriage of devices such as excavators, excavators, and track loaders plays an essential duty in sustaining the equipment's weight, providing security on numerous surfaces, and soaking up the influence of irregular surface areas. By spending in high-grade undercarriage components, drivers can substantially expand the life-span of their equipment and minimize the danger of unexpected breakdowns.One key benefit of making use of top quality undercarriage components is the enhancement of overall machine efficiency. Sturdy tracks, gears, idlers, and rollers decrease friction and make certain smoother activity, eventually resulting in increased productivity and performance on task sites. Reliable undercarriage parts lessen downtime for maintenance and fixings, enabling operators to optimize their operational hours and task due dates.

Usual Undercarriage Use Issues

Benefits of Timely Substitute

One key benefit of timely undercarriage component substitute is boosted maker uptime. By replacing worn parts prior to they fall short, the threat of unforeseen malfunctions is reduced, decreasing downtime for repair work and maintenance. This aggressive technique not only keeps the hefty equipment operational but additionally stops prospective damage to various other components that might arise from a falling short undercarriage.

Additionally, replacing undercarriage parts without delay can improve general performance. Investing in timely undercarriage component substitute is a proactive method that pays off in terms of boosted efficiency and decreased functional prices.

Choosing the Right Undercarriage Provider

Picking the appropriate undercarriage provider is an essential decision that considerably affects the efficiency and upkeep of hefty machinery. When choosing a provider for undercarriage components, click now numerous variables must be considered to make sure ideal performance and cost-effectiveness. It is necessary to analyze the distributor's reputation and experience in the industry. A respectable vendor with years of experience is most likely to supply high-grade components and trusted solution. Furthermore, consider the variety of products provided by the provider. A provider that uses a wide selection of undercarriage components for numerous hefty machinery brands and models can be advantageous as it gives extra choices to satisfy particular needs.Furthermore, examining the provider's customer care and assistance is essential. A distributor that provides superb customer support, quick action times, and technological support can aid reduce downtime and make certain smooth operations. Expense is additionally a significant aspect to consider; nevertheless, it needs to not be the sole go to website factor. When choosing the ideal undercarriage distributor for hefty equipment, balancing integrity, high quality, and cost-effectiveness is key. By thoroughly examining these variables, you can pick a distributor that fulfills your needs and adds to the efficient efficiency and upkeep of your hefty equipment.

Maintenance Tips for Extended Life-span

To make sure an extensive lifespan for heavy machinery undercarriage parts, carrying out an aggressive upkeep routine is important. Investing in high quality undercarriage components from trustworthy suppliers is equally essential for making sure durability. By adhering to these upkeep ideas faithfully, hefty equipment proprietors can maximize the efficiency and longevity of their undercarriage components, inevitably lowering downtime and functional prices.Verdict

In verdict, top quality undercarriage components are necessary for the effective operation of heavy machinery. Timely substitute of used parts weblink can protect against costly downtime and maintain optimum efficiency. Selecting a trustworthy vendor and complying with appropriate maintenance techniques are crucial to making sure the prolonged lifespan of undercarriage parts. By resolving typical wear problems and purchasing high-quality components, heavy equipment drivers can make best use of efficiency and reduce upkeep prices.

Extreme wear and tear on undercarriage parts of heavy machinery can lead to substantial functional difficulties and enhanced maintenance prices. Normal assessments, appropriate maintenance, and prompt substitutes of worn undercarriage parts are crucial to minimize these typical wear problems and ensure the optimum performance of heavy equipment.

A vendor that provides a wide option of undercarriage parts for various hefty machinery brand names and designs can be beneficial as it gives a lot more options to fulfill certain needs.

By adhering to these maintenance pointers carefully, heavy equipment owners can enhance the performance and longevity of their undercarriage parts, inevitably minimizing downtime and functional expenses.

Report this wiki page